Compact fuel filter modules with extra features

A compact fuel filter module from MANN+HUMMEL protects the European engines of the Medium Duty Engine Generation from Daimler and also the engines of the Daimler subsidiary Detroit Diesel. This is made possible by a number of integrated functions.

Regional logistics and deliveries into inner city areas require light and medium duty trucks. This is true in Europe and the USA. On the American market Daimler equips commercial vehicles and buses with 5.1 and 7.7 liter engines from the Medium Duty Engine Generation (MDEG). The manufacturer has developed the engine series with a power range of 219 to 350 kilowatts to make them especially suitable for these applications.

Reliable protection

Daimler uses the expertise of MANN+HUMMEL for the fuel filtration in the American DD5 and DD8 MDEG engines produced by Detroit Diesel. The compact module convinces with numerous functions. A pre-fuel filter protects the fuel feed pump against particles. The main filter convinces thanks to the MULTIGRADE F-MB 333.2 high performance filter media which is characterized by a filtration efficiency of 99.7 percent. The main filter also separates any water which may be present in the diesel. This is achieved with the proven three-stage water separation from MANN+HUMMEL. As a result, the fuel filter module is able to reliably protect the modern high performance injection systems of the diesel engines over their complete service life. The separated water is removed from the water collection bowl via a water drain plug located on the upper side of the module.

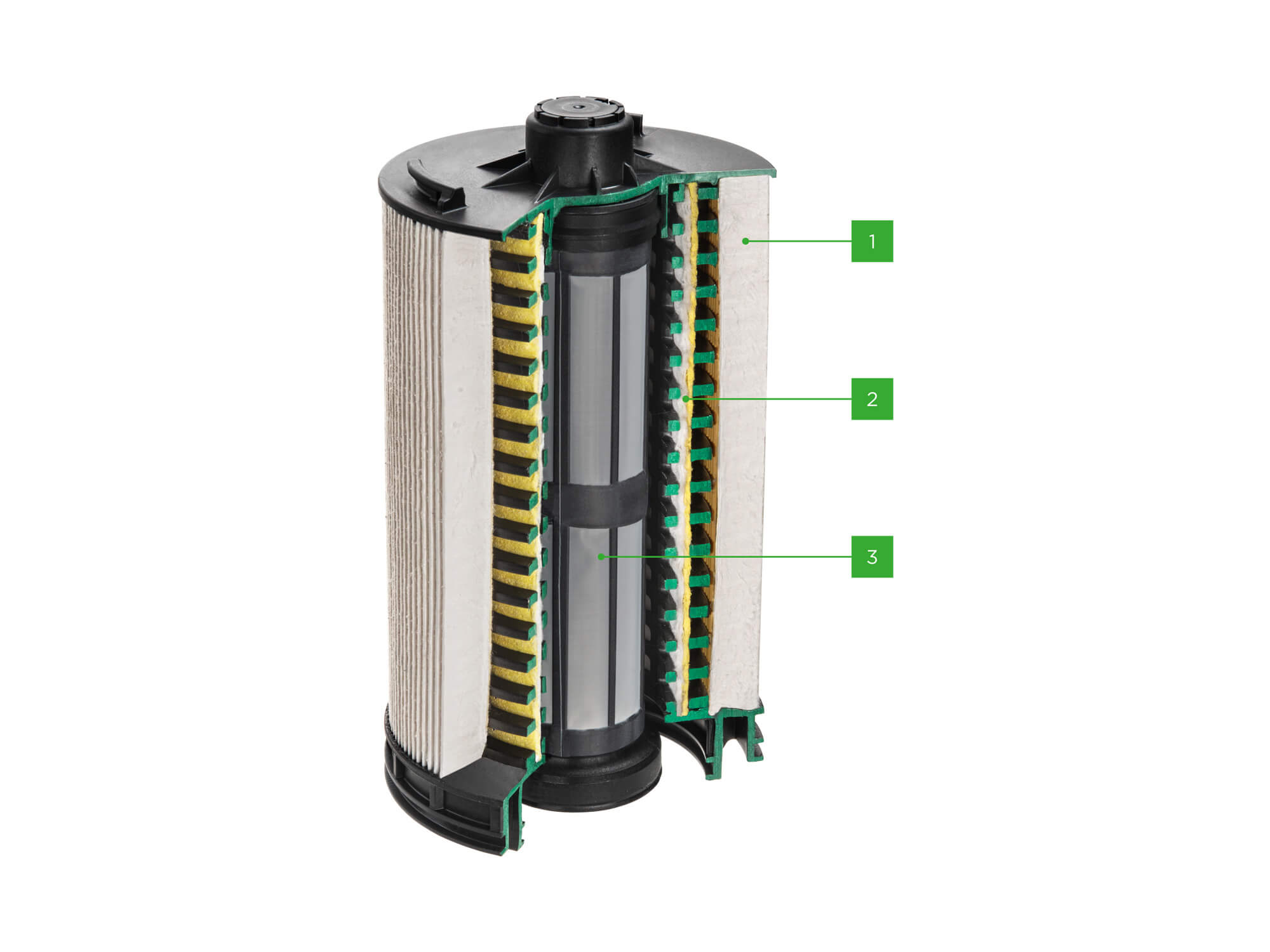

Filter element with three-stage water separation

Filter element with three-stage water separation

1 Step 1: Separation of particles

2 Step 2: Coalescence of water droplets

3 Step 3: Separation of water

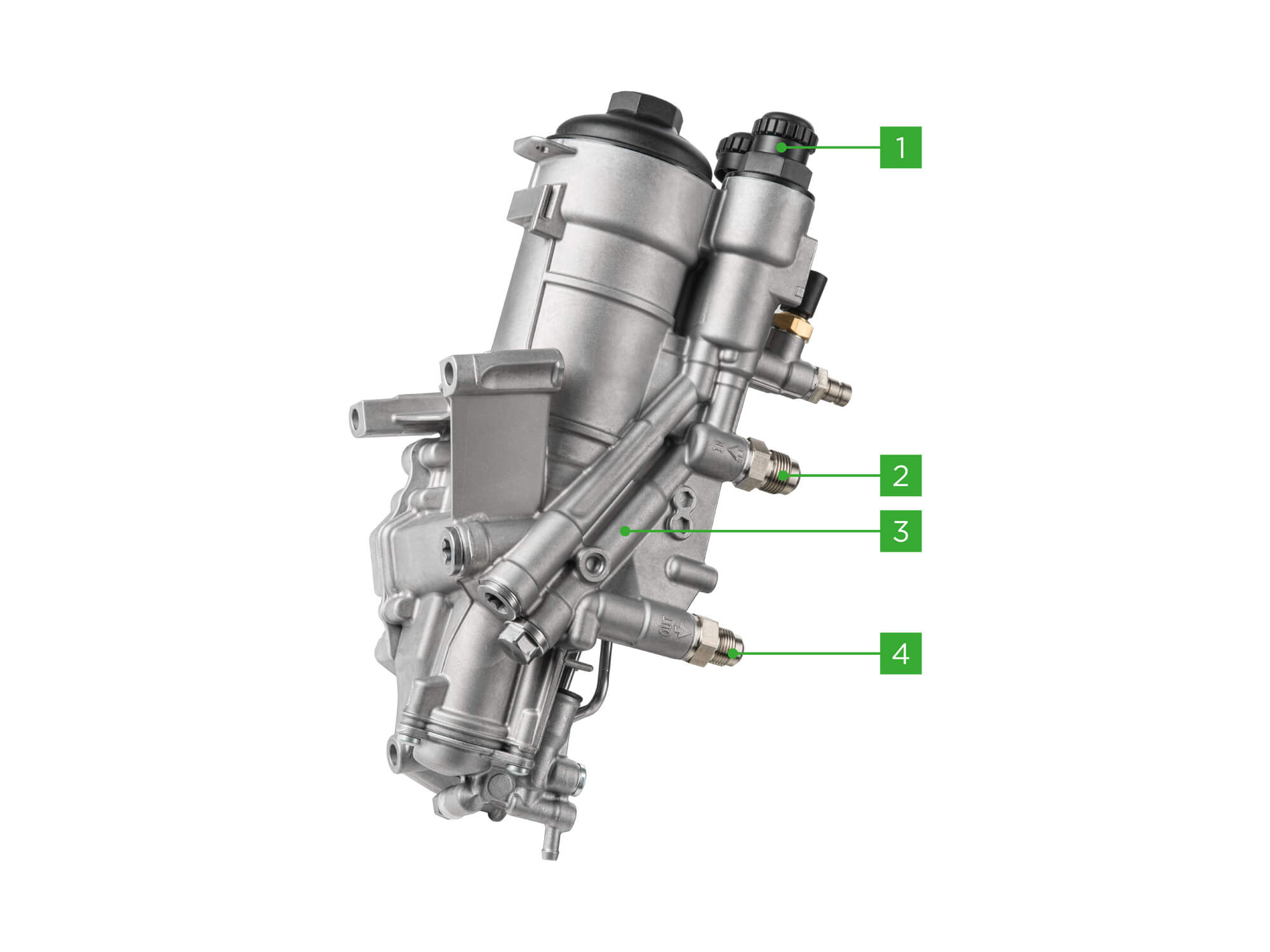

Setting standards when it comes to venting

The engineers came up with some ingenious solutions to enable a quick and easy service, realize efficient venting of the filter module and at the same time protect the clean side of the fuel system against contamination during the filter change. An important role is played here by the service valve which during the filter change closes the clean fuel area of the module to the fuel side and only opens again after the new element has been installed in the housing. This mechanism prevents unfiltered fuel from penetrating the clean side. When the service is finished, the mechanic fills the module with fuel again using a hand pump integrated in the pre-fuel filter. Residual air in the module on the dirty side and clean side is vented via helical channels into the upper filter element end disk. In order to prevent a return flow of air causing problems when the engine is started, a sufficient amount of fuel always remains in a siphon to prevent air flowing back via the return line.

1 Pre-fuel filter with hand pump

2 Fuel supply connection to tank

3 Recirculation heater

4 Fuel return connection to tank

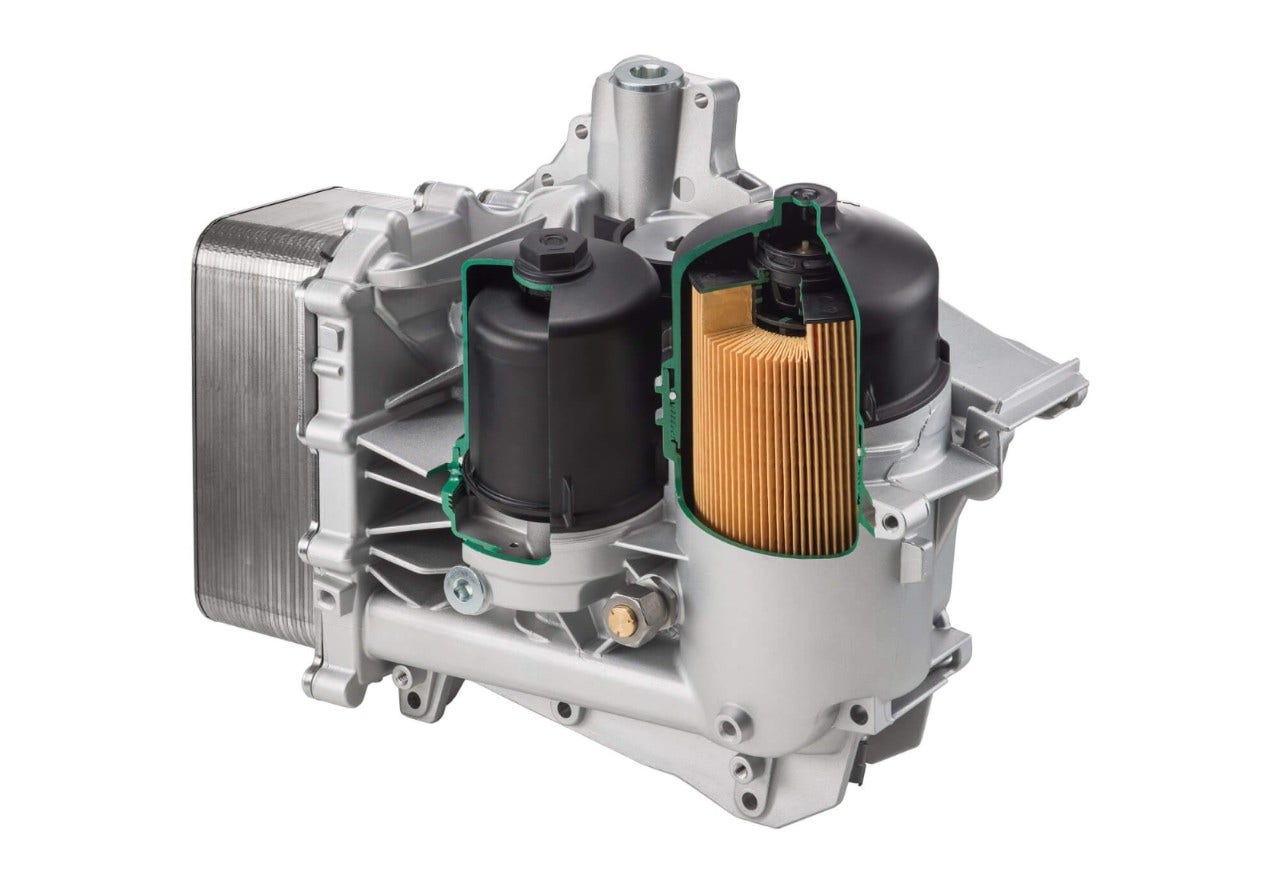

Fuel filter module for the 5.1 and 7.7 liter engines of the Medium Duty Engine Generation of Daimler

Fuel filter module for the 5.1 and 7.7 liter engines of the Medium Duty Engine Generation of Daimler

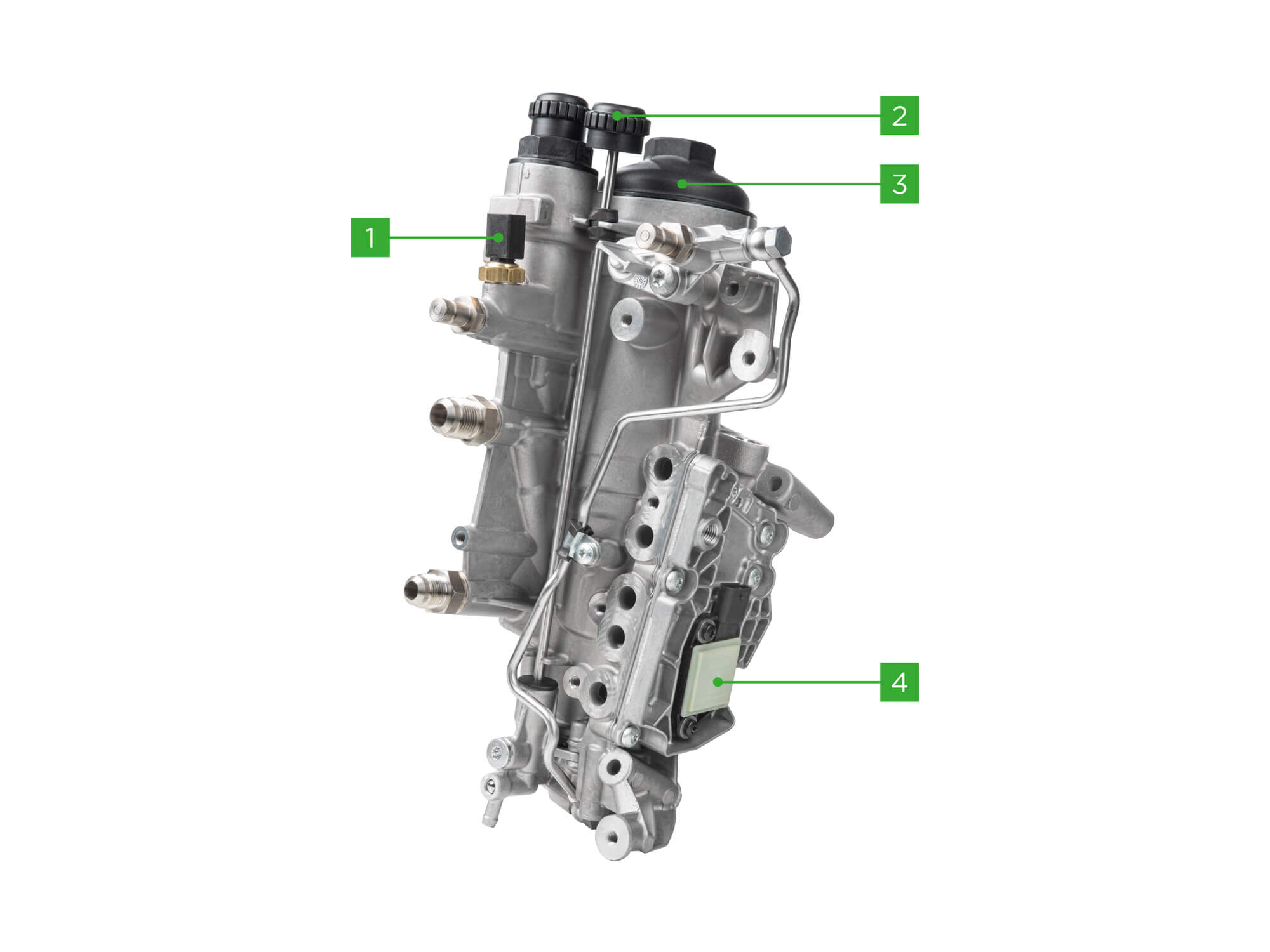

1 Temperature sensor

2 Water drain plug

3 Main filter with three-stage water separation

4 Water sensor

Float ball regulates water level

MANN+HUMMEL uses a new tank return valve in the fuel filter module which has a patent pending. If the draining of the separated water is not made in time, the valve opens a return line to the fuel tank. A float ball, which due to its density is lighter than water but heavier than diesel fuel, is always located exactly between the water and the fuel. If the water level rises, the float ball is pressed upwards and as a result automatically opens the drainage channel. When sufficient water has drained off, the float ball lowers to its original position. The channel is then closed again. This intelligent solution ensures that an excess of water does not collect in the module and that no fuel flows back to the tank, which is unused.

The fuel filter module is also able to manage extreme conditions. The robust housing of the module is able to withstand temperatures up to 150 degrees Celsius. In order to prevent clogging of the pre-fuel filter caused by fuel paraffin crystals under cold operating conditions and to improve the fuel flow, a recirculation line to the pre-fuel filter is integrated in the module. In this process warm fuel coming from the engine is mixed with cold fuel coming from the tank. This ensures that commercial vehicle engines are perfectly protected at all times.

Advantages at a glance

- Proven three-stage water separation

- Integrated hand pump for filling the module after service

- Service valve to protect the clean side

- Newly-developed venting of the module via helical channels after service

- Float ball to control water level in the module

- Integrated recirculation protects pre-fuel filter under cold conditions