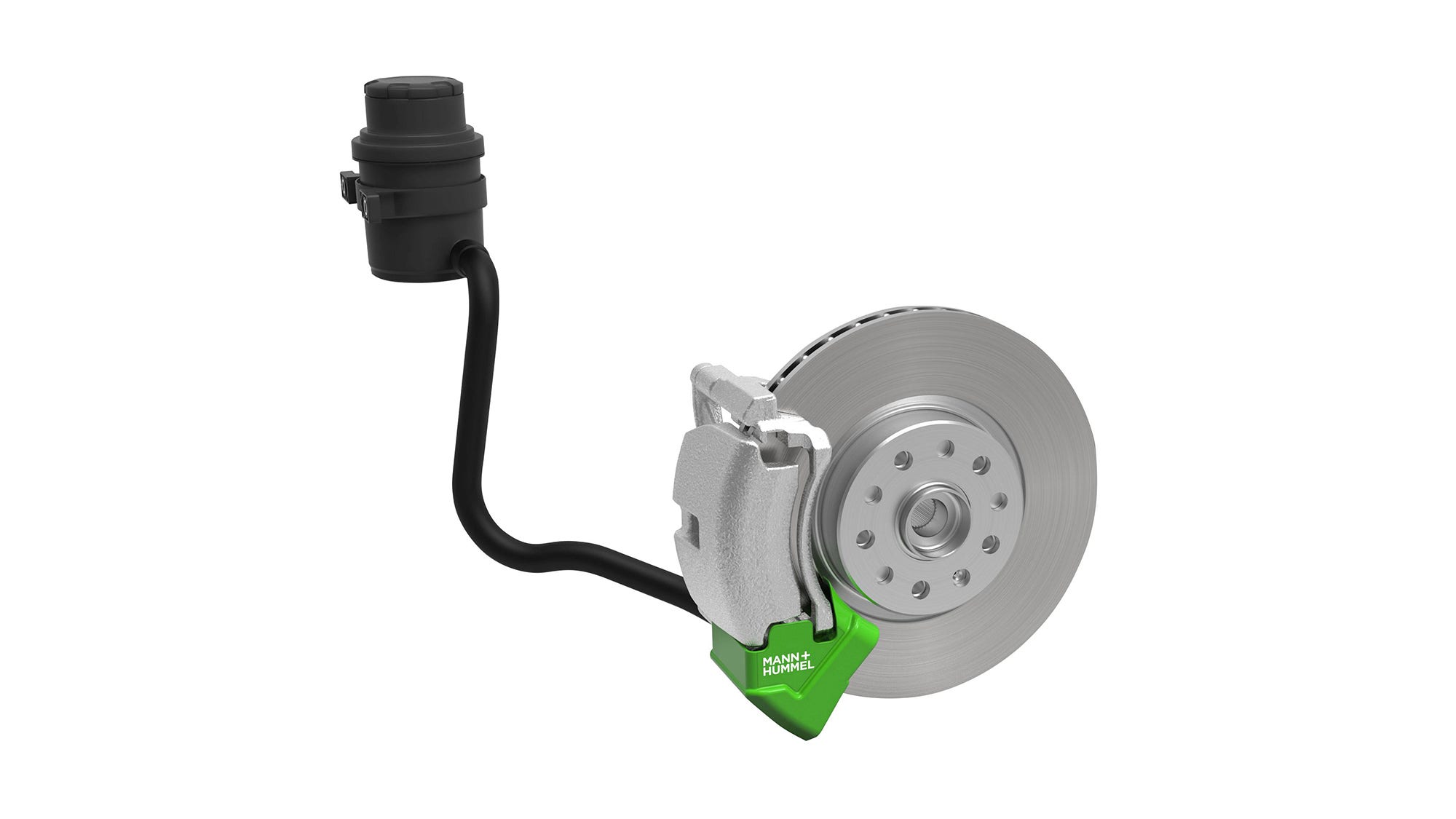

Brake dust particle filter

Fine dust is a danger to human health and pollutes the environment. The passive brake dust particle filter from MANN+HUMMEL with non-woven metal fibers is fitted directly to the caliper and directly retains particle emissions on the brake. The filter fits in all existing installation spaces and can be adapted to different brake sizes and concepts.

Product benefits

- Reduces brake dust emission directly at the source

- Easy, fast and clean service

- Robust design fits in all existing installation spaces

- Passive filter system, no energy consumption

- Use for all vehicles and propulsion systems possible

MANN+HUMMEL also has an active version of the brake dust particle filter in its portfolio. This collects the brake dust and fine dust produced at the brake and transports it to a central filter via a vacuum pump.