Oil mist solutions by MANN+HUMMEL

People spend a large part of their lives at work. That’s why it is crucial to be able to breathe freely there. In industrial working environments, in particular, the level of pollutants in the air is often significant. Industrial work processes such as plastics processing, metal forming, metal heating or die casting cause polluted air quality - often with drastic consequences for people and machines.

MANN+HUMMEL uses two technologies in oil mist separation:

- Mechanical oil mist separation according to VDI 3677 (ScandMist)

- Electrostatic oil mist separation according to VDI 3678 (TriMist)

Clean and safe workshop environment by eliminating oil mist, oil smoke and emulsion mist

No cleaning and maintenance downtime with our oil mist collectors

Savings in operating costs due to energy-efficient EC motors in combination with a closed control loop

Premium, long-lasting, and high separation efficiency of 99.95%

Increased availability of production machines

Oil mist is generated in various industrial environments. Especially in metalworking, the air quality can be significantly impaired during grinding, machining or hardening. In molding and joining processes with plastics, hazardous vapors are also generated by thermal stress or the use of solvents. Likewise, the production of textiles brings with it the danger of oil mists and vapors. Our oil mist separators for machine tools provide protection wherever it is needed. So in an industrial context, using an oil mist filter from MANN+HUMMEL always means protecting people and the environment as well as increasing machine performance and productivity and optimizing downstream processes.

Be part of the MANN+HUMMEL community

Log in to your account to access a wide range of products, enjoy a tailored purchasing experience, and receive dedicated support from our experts. You don't have an customer account yet? Request your shop login today!

Oil mist collectors from MANN+HUMMEL are revolutionary

Wherever materials are processed industrially, air pollution can occur in the form of oil mist, oil smoke or emulsion mist. Workers may be exposed to air pollution especially in metalworking, but also in plastics processing and textile manufacturing. The composition of this pollution varies considerably depending on the process, but basically consists of a complex mixture of toxic pollutants - including oil, water, additives, metal chips, bacteria and more.

Choosing a filter that matches your maintenance schedule is crucial. For environments with high dust loads, a self-cleaning filter or one with extended service intervals reduces downtime and labor costs.

Inhaling oil mist poses high health risks and should be avoided at all costs. The tiny droplets of oil mist in the air penetrate deep into the lungs and can cause permanent respiratory problems. Skin can also suffer when in contact with oil mist, resulting in conditions like oil acne and dermatitis.

Other problems relate to workplace safety. Oil particles in the air increase the risk of slipping. This creates the perfect environment for workplace accidents. In addition, oil mist can lead to fires and explosions if the aerosol concentration is particularly high.

Many machines today are electronically controlled. If they are permanently exposed to oil mist, this leads to contamination and, in the worst case, defects. This in turn means long maintenance and downtimes, and productivity drops.

The environment also suffers from the release of oil droplets into the air, because emulsions and oils are released uncontrollably into nature with the oil mist. An oil mist extraction system at the source is the most efficient solution to protect nature, people and machines.

Even the naked eye can detect when oil mist is formed. If this is particularly pronounced, oily residues on machines and in the workshop environment are also visible. Another natural detector for oil mist is the nose. If there is a heavy, typical smell of oil in the air, this is another indicator.

The limit value for oil mist in Germany is 0.5 to 10 mg/m³, depending on the coolant. To ensure that this is not exceeded, we recommend using an emulsion mist separator.

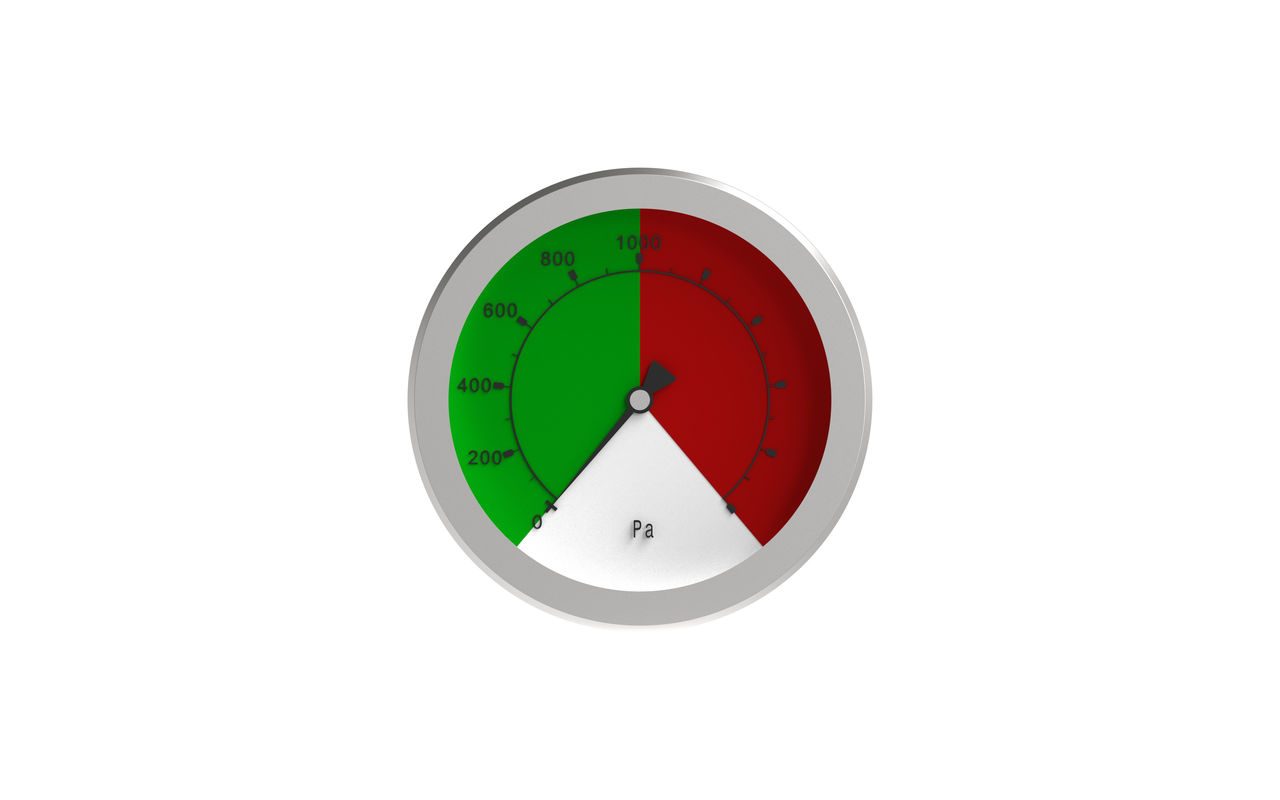

Pressure Gauge

Discover the precision and reliability of the ScandMist range of pressure gauges from Mann und Hummel. These high-quality pressure gauges provide accurate pressure measurements and are specially designed for demanding applications. Manufactured from robust materials, they ensure a long service life and consistent performance, even under extreme conditions.

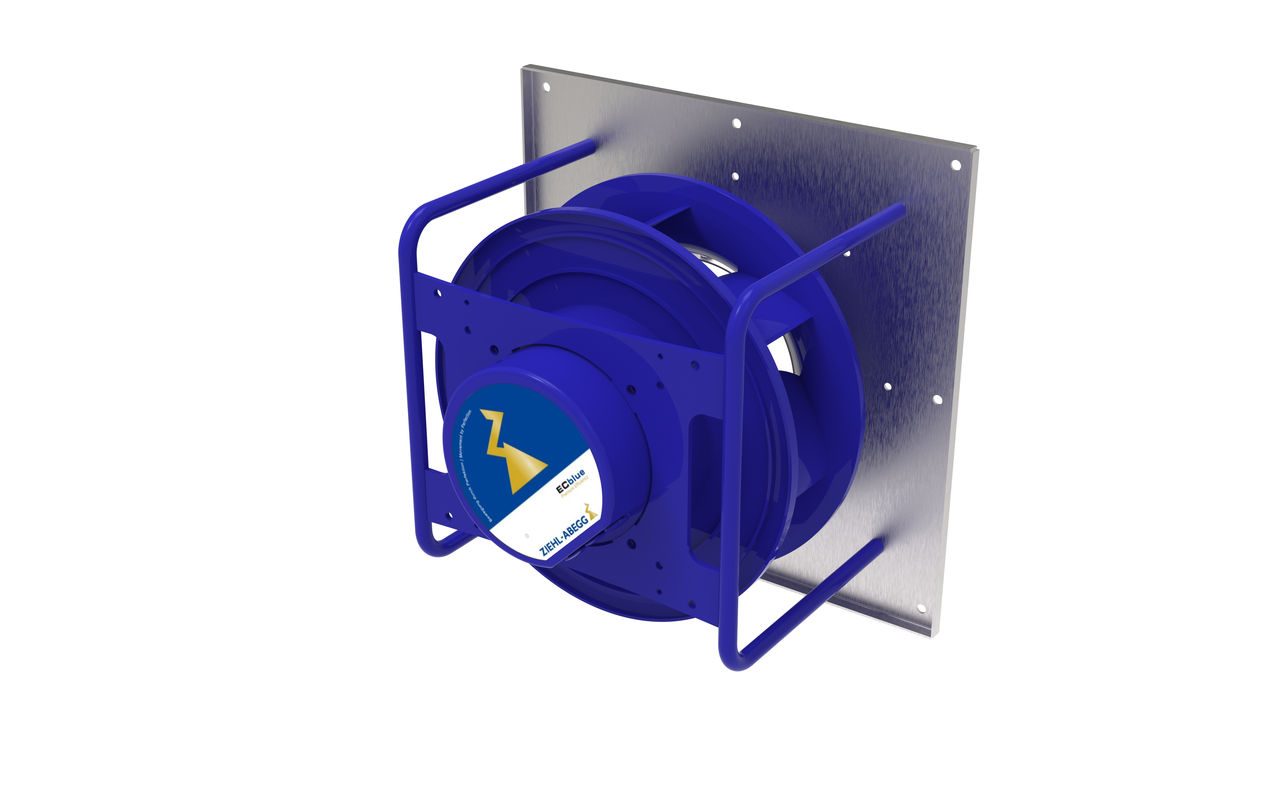

Ventilator

High-Performance Motor Unit

Powerful Motor: Equipped with a 3.7 kW motor for high efficiency and outstanding performance.

Robust Design: Constructed from durable materials to ensure a long service life.

Micatrone

High-precision sensors for monitoring and controlling differential air pressure in sensitive environments. It supports digital communication, automated calibration, and meets strict quality standards. Commonly used in cleanrooms, laboratories, and industrial ventilation systems.

Oil Mist Filter Elements

Our high-performance replacement filter elements are designed to ensure reliable and efficient separation of oil mist in industrial environments. Suitable for a wide range of oil mist collection systems, these elements help maintain clean air, protect equipment, and support compliance with environmental standards. With durable materials and high filtration efficiency, they offer long service life and easy installation for minimal downtime.