Convincing production expertise

For its 3.0 liter 6-cylinder diesel engines Jaguar Land Rover has opted for a passive intake manifold from MANN+HUMMEL. In addition to extensive engineering expertise, MANN+HUMMEL is demonstrating its wide-ranging competence in production.

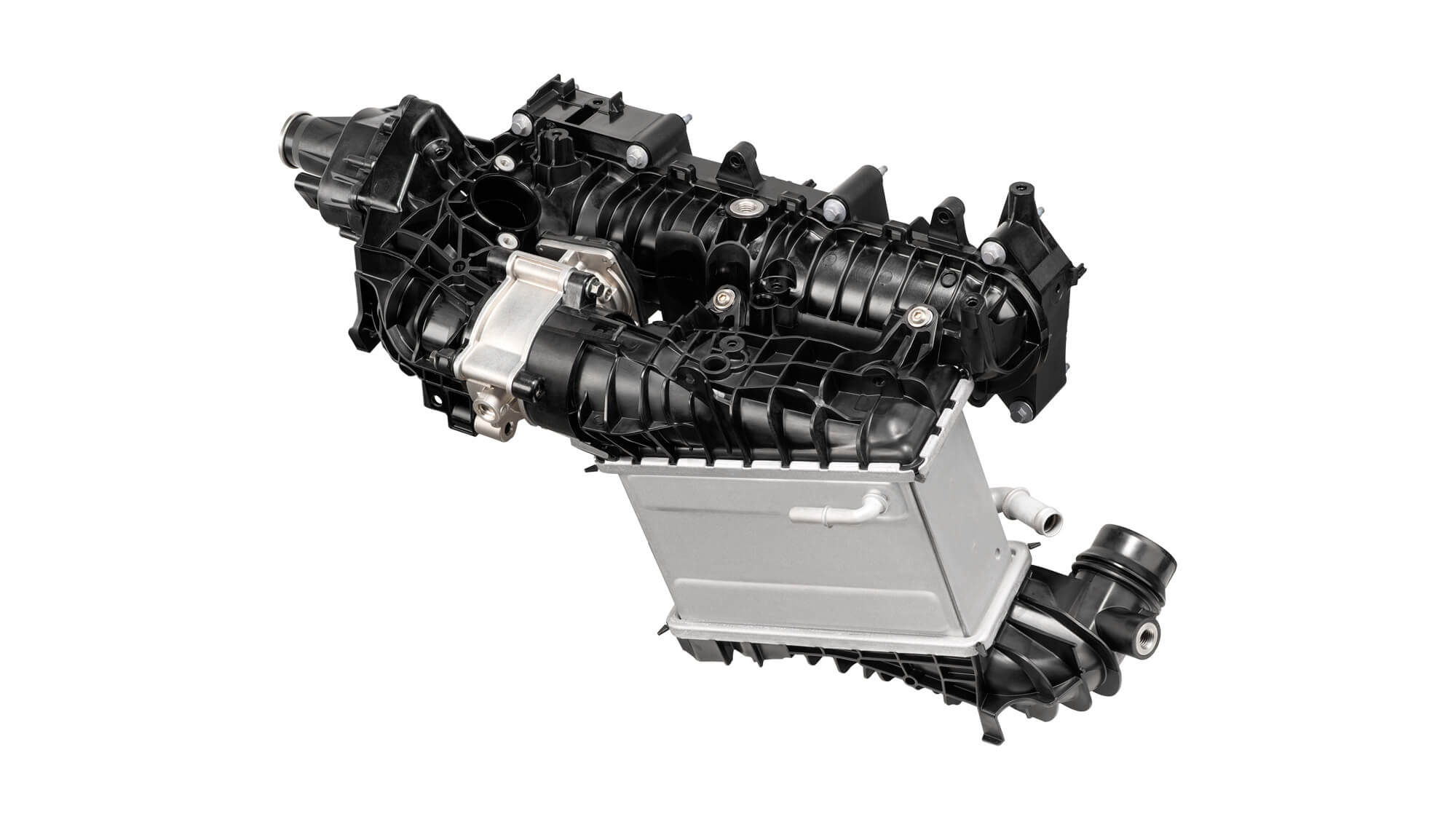

Passive intake manifold for the 3.0 liter 6-cylinder diesel engines from Jaguar Land Rover

Passive intake manifold for the 3.0 liter 6-cylinder diesel engines from Jaguar Land Rover

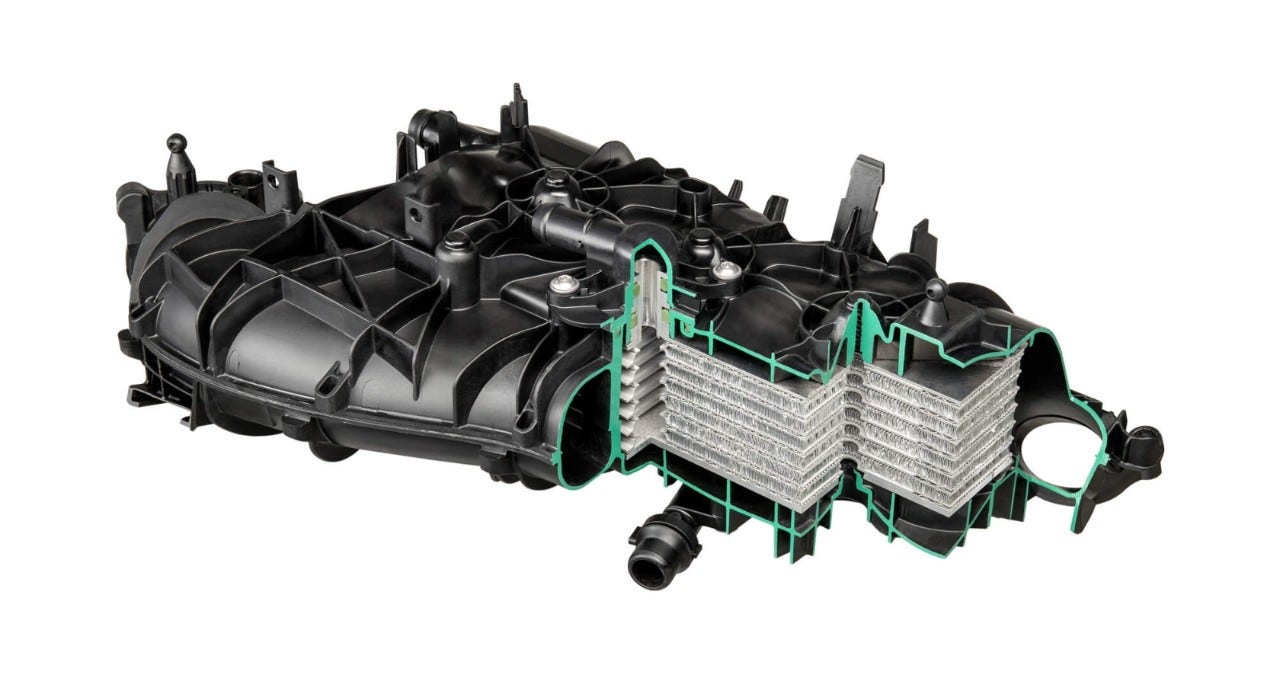

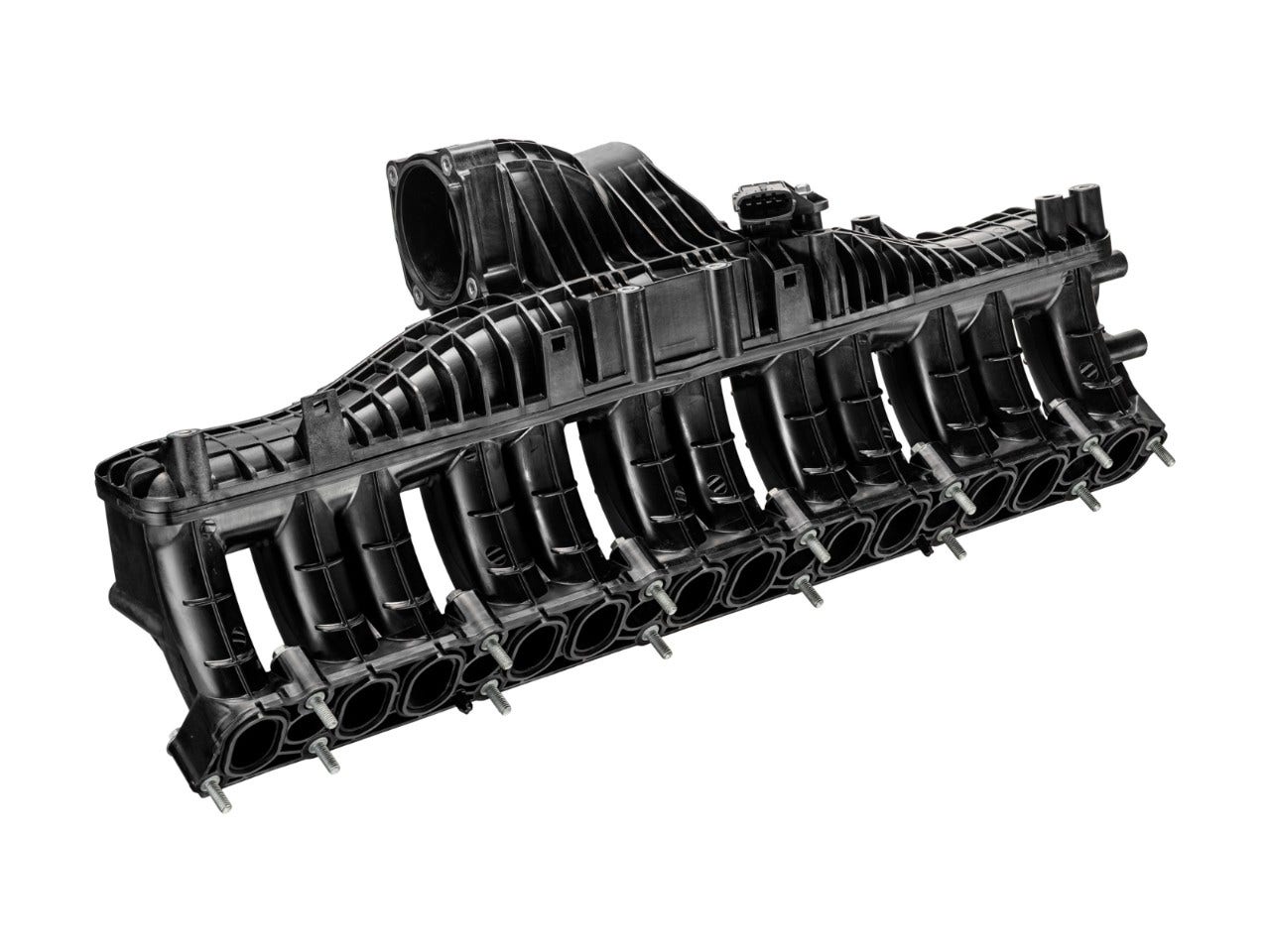

For the latest order from Jaguar Land Rover the engineers at MANN+HUMMEL had to think in new dimensions. They developed a passive intake manifold for the 3.0 liter 6-cylinder diesel engines of the British manufacturer which is now in production. The intake manifold consists of a top shell to the throttle body and a lower shell to the cylinders. Both halves are joined using vibration welding. Due to the component size of 60 centimeters this is not an easy task. MANN+HUMMEL solved this challenge by fully exploiting the tool installation space of the injection molding machine.

In order to meet the high requirements with regard to temperature stability, the intake manifold is made from PA6.6-GF35. Curved areas combined with pronounced ribbing ensure that the intake manifold can withstand high charge air pressures and pressure pulsation cycles. That makes the demolding of the shells a complex operation. The tools have to open in different directions. MANN+HUMMEL solved this task through a number of sliders and lifters which were adapted to the curvature of the channels in the component. That reduces the number of additional components and welding processes.

With a flange to the electric throttle body and an exhaust gas recirculation inlet the intake manifold is also equipped with an integrated temperature and pressure sensor. The complex component geometry also required a well-thought-out tool concept for the welding and demolding. Welding jigs with special inserts were used to generate the required force on the welding surface.