Robust fuel filter modules for power trucks

MANN+HUMMEL is now also supplying an innovative fuel filter module for power trucks in the heavy duty range to Daimler.

The newest generation from the heavy engine platform from Daimler is characterized by low fuel consumption and impressive driving dynamics. MANN+HUMMEL has developed an innovative fuel filter module for the Mercedes-Benz trucks Actros und Arocs with 10.7 liter engine. Here the filter developers were in particular faced with the challenge of integrating the large number of valves required by the complex fuel circuit in the engine and also meeting the high requirements regarding the robustness of the component.

MANN+HUMMEL fuel filter module integrates a number of functions

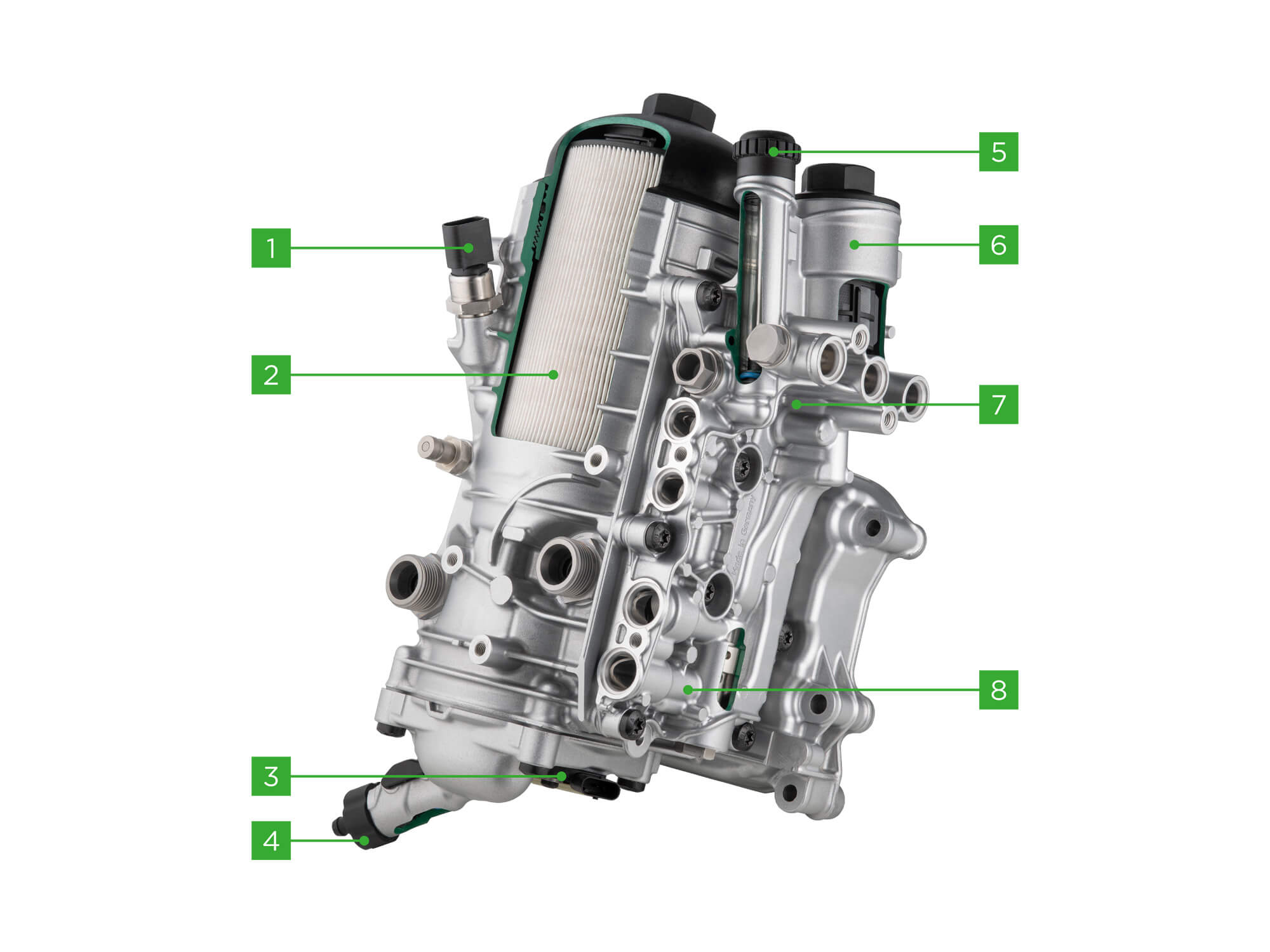

MANN+HUMMEL fuel filter module integrates a number of functions

1 Pressure sensor

2 Main filter with three-stage water separation

3 Water sensor

4 Water drain plug

5 Hand pump

6 Pre-filter

7 Recirculation valve

8 Overpressure valve

Water separation for the highest requirements

The filter module for the heavy engine platform includes a pre-filter to protect the low pressure fuel pump. The injection system on the high-pressure side is protected by a main filter fitted with the high performance MULTIGRADE F-MB 333.2 filter media with a fiberglass layer and a filtration performance of 99.7 percent. In addition, proven three-stage water separation developed by MANN+HUMMEL is integrated in the element. In comparison to other fuel filter modules, in this application the volume flow is exceptionally high. In order to prevent coalesced water droplets under these operating conditions from being swept through the hydrophobic barrier over to the clean side, the developers at MANN+HUMMEL maximized the sedimentation gap between the stages of the water separation to fully exploit the installation space. This allows water droplets to drop down into the water collection bowl before they reach the hydrophobic barrier. As an option, a water sensor can be integrated to indicate when the maximum water level in the module has been reached and the water collection bowl needs to be emptied via a drain plug.

In order to protect the system in case the draining of the separated water is not made in time, the fuel filter module has a patented tank return flow solution with a float ball. The ball used is lighter than water, but heavier than diesel fuel and is therefore always positioned exactly between the water and the fuel. When the water level in the water collection bowl rises above the permissible limit, the ball also rises and opens the return channel to the tank. After a sufficient amount of water has run off, the ball goes back to its original position which causes the channel to close. This solution ensures that no water can reach the clean side and that unused fuel can return to the tank.

Impressions from the clean room production in Ludwigsburg

- Installation of the filter element

- Rotation of the machine

Easy and clean service

Further advantages of the solution which has a patent pending are that it enables a quick, uncomplicated and clean service. When the filter element is removed, a service valve closes the access to the clean side of the module and thus prevents the entry of unfiltered fuel. The valve only opens again when the new filter element has been correctly inserted in the housing. After that the service technician fills the module with fuel. This is made using the integrated hand pump or using an external pump system which can be connected via a quick coupling. In order to remove the air which has entered the fuel filter system during the service, special spiral-shaped channels were integrated in the upper cover of the filter element. The channels ensure that air present inside and outside of the filter element can be directed from the filter module back into the tank return channel. A siphon also integrated in the upper cover prevents air from quickly entering the fuel module when the engine stops.

In spite of its above-average performance, the compact filter element achieves a service interval of 150,000 kilometers. It is protected against pressures above 15 bar by an additional overpressure valve integrated in the fuel filter module. The filter element is robust and able to withstand high temperatures up to 130 degree Celsius. Therefore, it fulfills all the requirements of modern high performance injection systems. The fuel filter module is manufactured in the clean room production in Ludwigsburg.