Ultra fine filtration with new fuel filter media

The filtration experts at MANN+HUMMEL have now developed fuel filter media which are even more efficient to meet the future requirements for fuel filtration. In this process, new measuring and testing methods are also used.

MANN+HUMMEL has always attached great importance to having a product range able to meet the requirements of today and also of the future. In line with this strategy, the filtration specialist constantly evaluates the need for optimization. Under the critical eyes of the experts, the measuring and testing methods are regularly reassessed. This is necessary because the ability to measure particles is a condition for determining whether a filter media, for example, can protect highly sensitive injection systems against smallest particles.

MANN+HUMMEL uses a new low viscosity multipass test bench to carry out field simulations. In the categories of particle separation and dirt holding capacity, improvements made to the test bench have now resulted in the measurement of particle sizes from one to three micrometers. In addition to verifying the performance, the test bench integrates further functions such as static and vibration inspections with the aid of a shaker.

Improvement of the filter media range

Decades of expertise in the area of fuel filtration as well as market and customer proximity enable MANN+HUMMEL to systematically further improve its filter media range and achieve an even higher separation efficiency. Based on the proven fuel filter media MULTIGRADE F-MB 333 which is already used as standard in heavy duty and industrial applications, the experts firstly developed the MULTIGRADE F-MB 2000, which has a separation efficiency of 99.95 percent for particles with a size of four micrometers and is also available on the market. MANN+HUMMEL is currently working on the filter media MULTIGRADE F-MB 10000, which further improves particle separation efficiency thanks to an improved gradient structure. The separation efficiency is 99.99 percent for particles with a size of four micrometers. The first filter elements with this media will undergo tests in the field in 2020.

The fuel filters of the latest generation effectively protect modern injection systems against contaminants by retaining smallest particles. This considerably lengthens the service life of system components such as the high pressure pump and the injectors. It also enables the homogeneous atomization and complete combustion of the diesel. High resistant filter media also perform their function with lower fuel quality or adverse operating conditions by ensuring the required purity of fuel in the injection system and therefore provide protection against wear and contaminants. This helps to avoid downtimes.

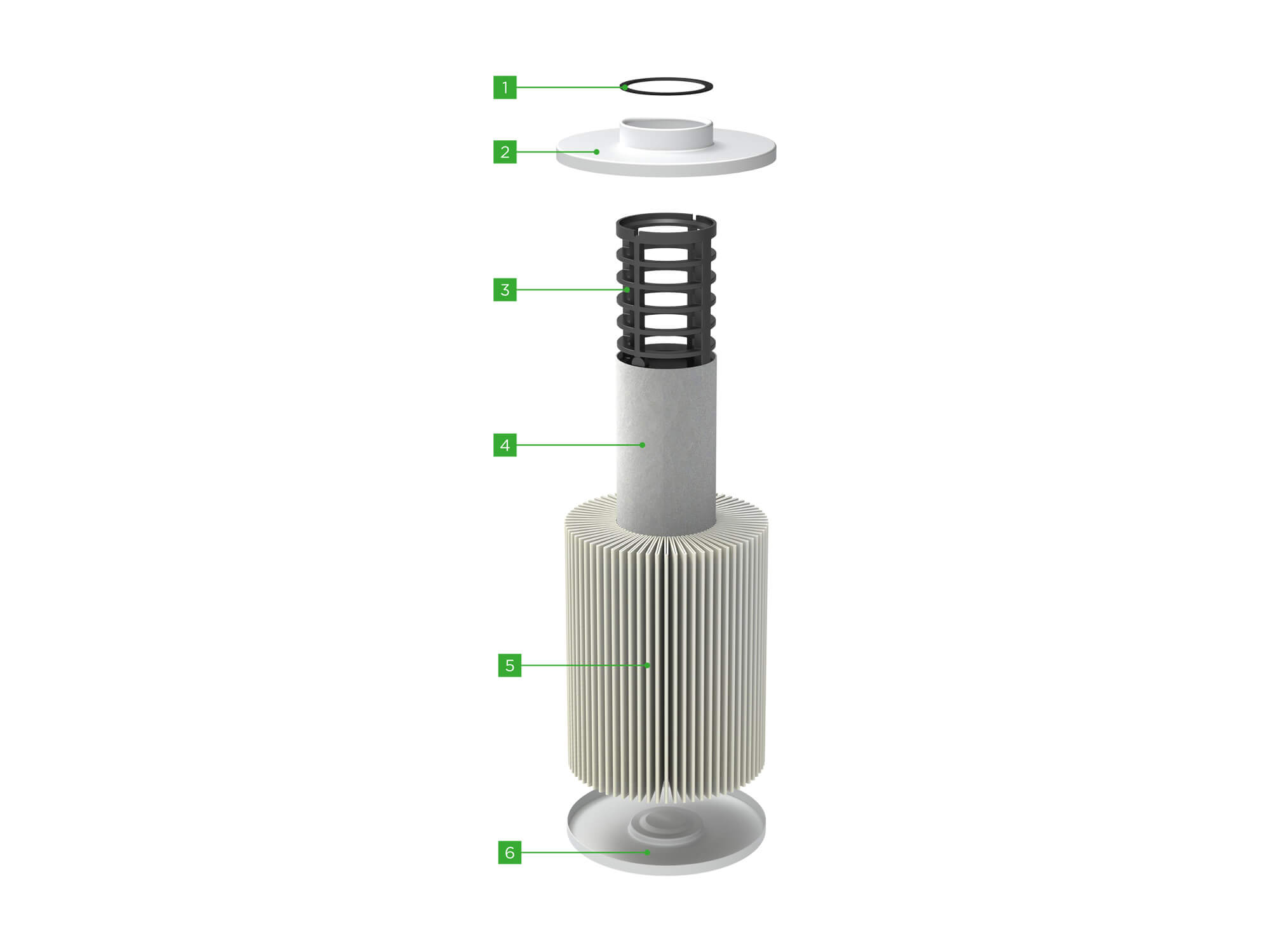

The fuel filter elements which are equipped with the media are a witness to the innovative strength of the filter manufacturer. They can be flexibly adapted to existing installation spaces and for different applications ranging from car engines to commercial vehicle engines for on-road and off-road applications and also industrial engines. A center tube in the element ensures excellent stability and a fully-synthetic protection layer prevents glass fibers from the layers of the media penetrating the fuel system. Measurements are made using a new measurement method developed by MANN+HUMMEL. This enables the improved detection of individual glass fibers in the fuel flow. Customers therefore benefit from the holistic approach of the filter specialist in the development of highly efficient filter media.